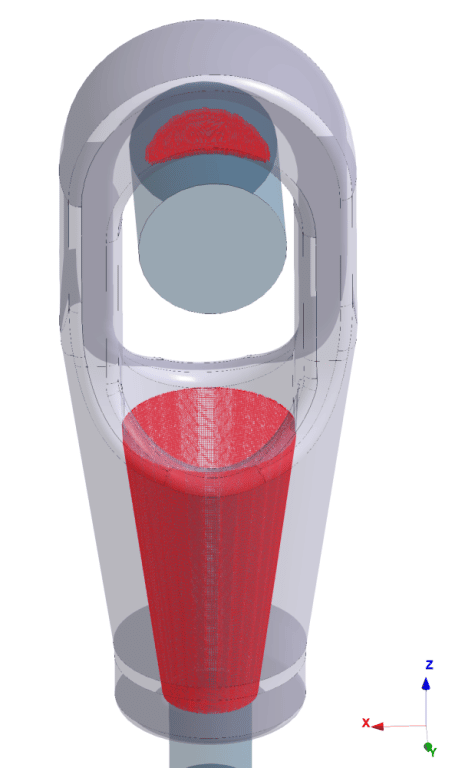

Wire inlet cylindrical

The conical wire inlet area is one of the critical areas of the socket. That is why we designed our AqualLine wire inlet cylindrical; to withstand the high pressure forces, and to help stabilize the socket when a socketing resin is poured.

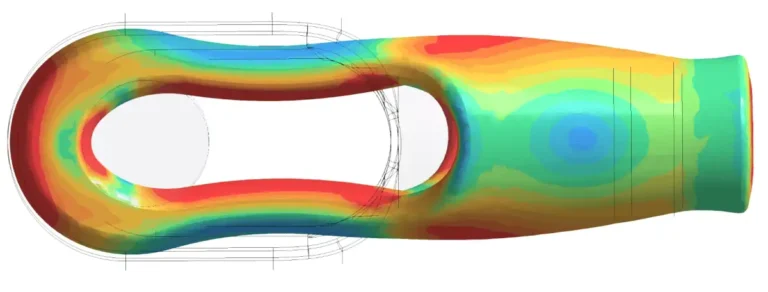

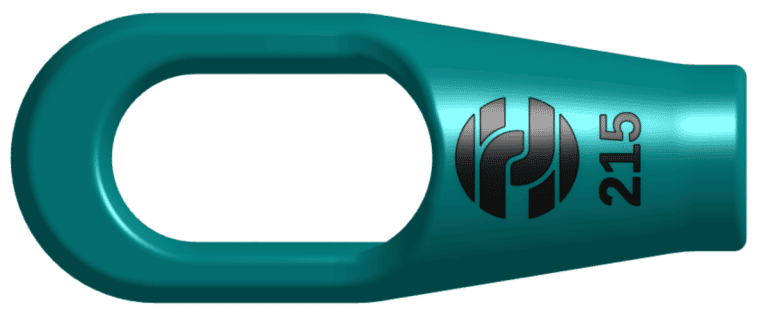

The geometry of the bow has also been changed to withstand higher forces. These are changes that do not affect the connection dimensions, but do ensure that the re-designed socket is more easy to handle, has better contact surface areas between family parts and is +10% stronger!

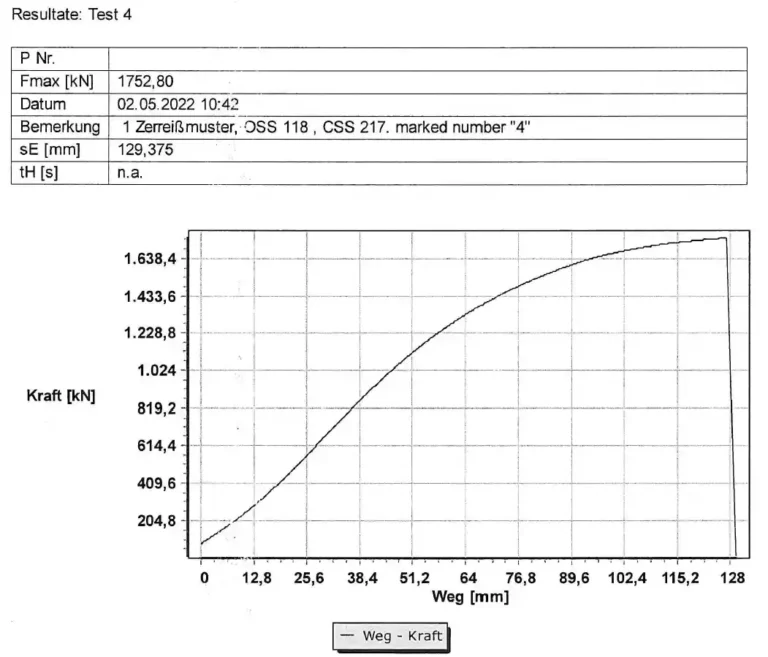

After a FEA Structural simulation analysis with linear and non-linear load cases, our sockets were subjected to fatigue and break load tests. During this multiple test work, the high performance 2160 grade steel wire ropes snapped. The sockets proved to be 1 to 2% deformed and no cracks were found during the MPI examination.

Check our design philosophy for more technical background info on how our AqualLine products make the difference. We continue where others stop.